Reduce Operating Expenses

Disposable media equipment may be initially less expensive but the costs quickly multiply – even short term. With the ClearAmine™ automated self-cleaning system there are no bags or cartridges to purchase, no material to inventory and track, no hazardous waste landfill fees, and greatly reduced maintenance and handling costs. Over a 10-year period, almost a 60% savings compared to a disposable media system can be recognized.

Increase Plant Safety

Minimize or eliminate exposure to hydrogen sulfide and other dust and fumes, because there are no cartridges or bags to change out. Lower labor interaction will contribute to the safety of operations.

Improve Filter Productivity

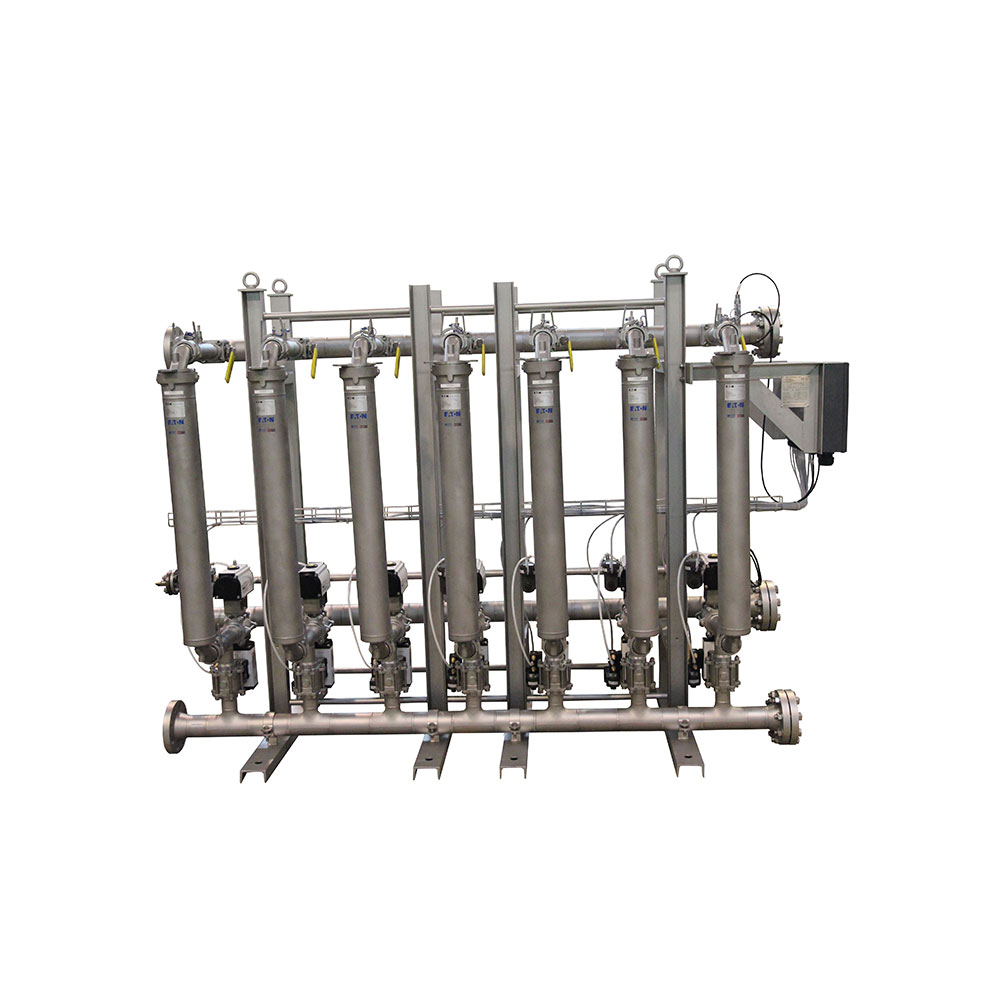

Continuous amine filtration is achieved through a slipstream process on single unit systems. For larger or more complex operations, Eaton provides a multi-bank configuration that enhances amine filtration. The level of contaminates within the amine solution is maintained at a specified limit to protect online equipment without compromising productivity.

Decrease Carbon Footprint

The ClearAmine system provides an opportunity to be proactive concerning environmental stewardship. The self-cleaning filter uses no cartridges or bags that can contribute to the ever-increasing content of landfills. Businesses can reduce the environmental impact of gasses associated with the decomposition of spent material.

Cut Labor Cost

Engineered with superior mechanical integrity, the ClearAmine System provides for enhanced serviceability, reduced maintenance, and zero downtime costs. The near fully automated system keeps the level of operator interaction to a minimum.