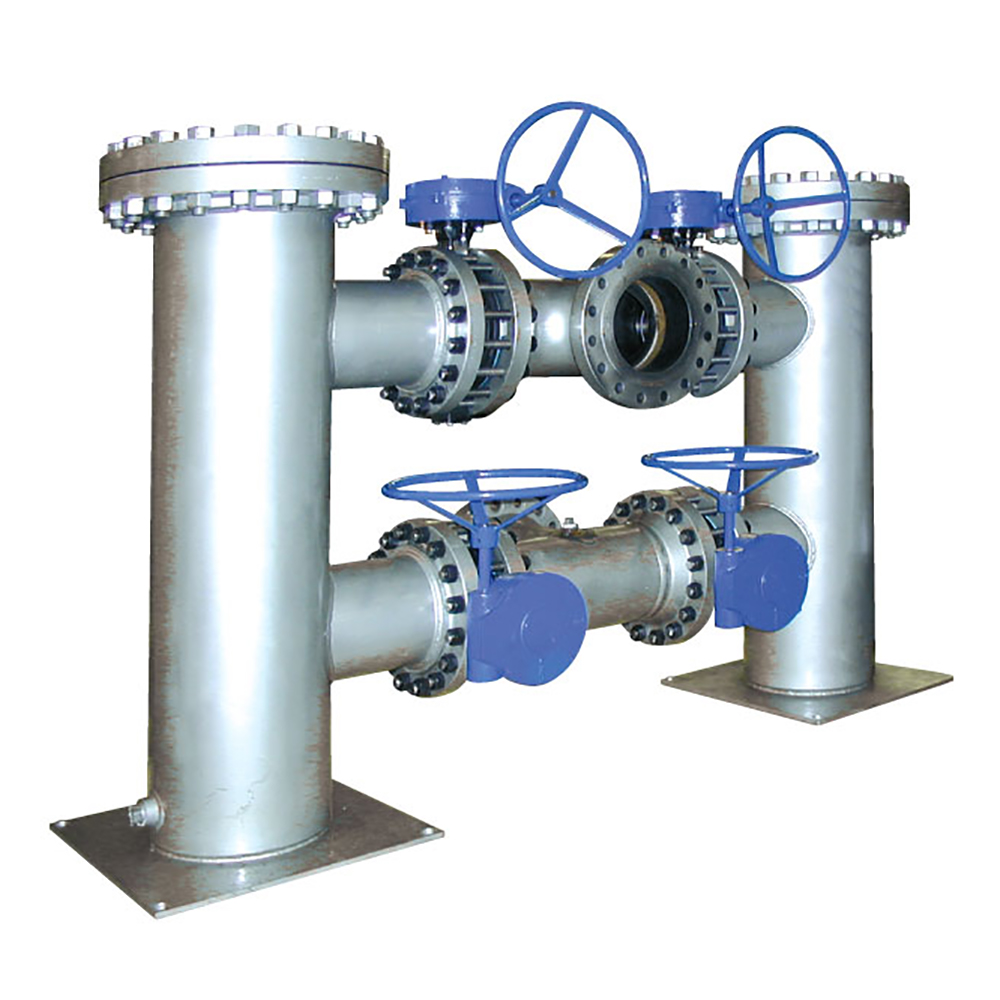

Series CLC Coalescers

Series CLC Coalescers Gas Liquid Separators

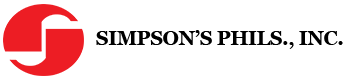

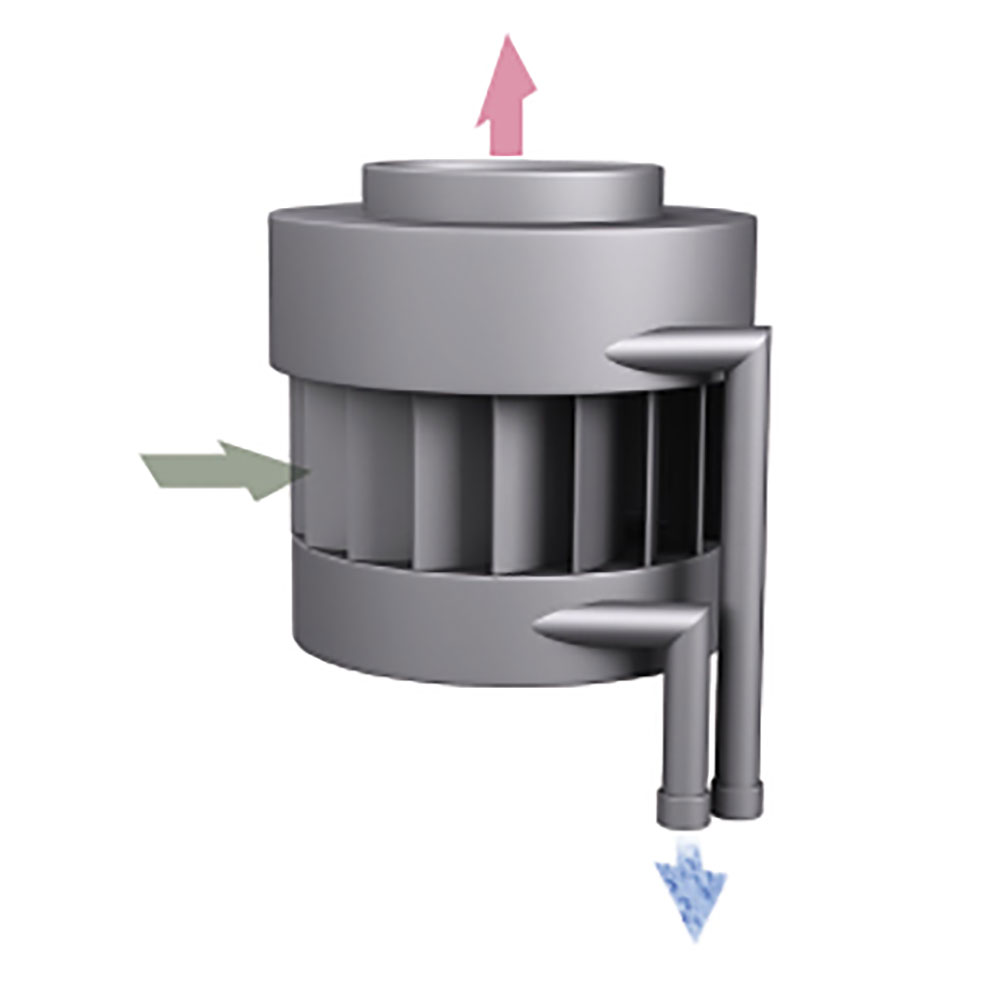

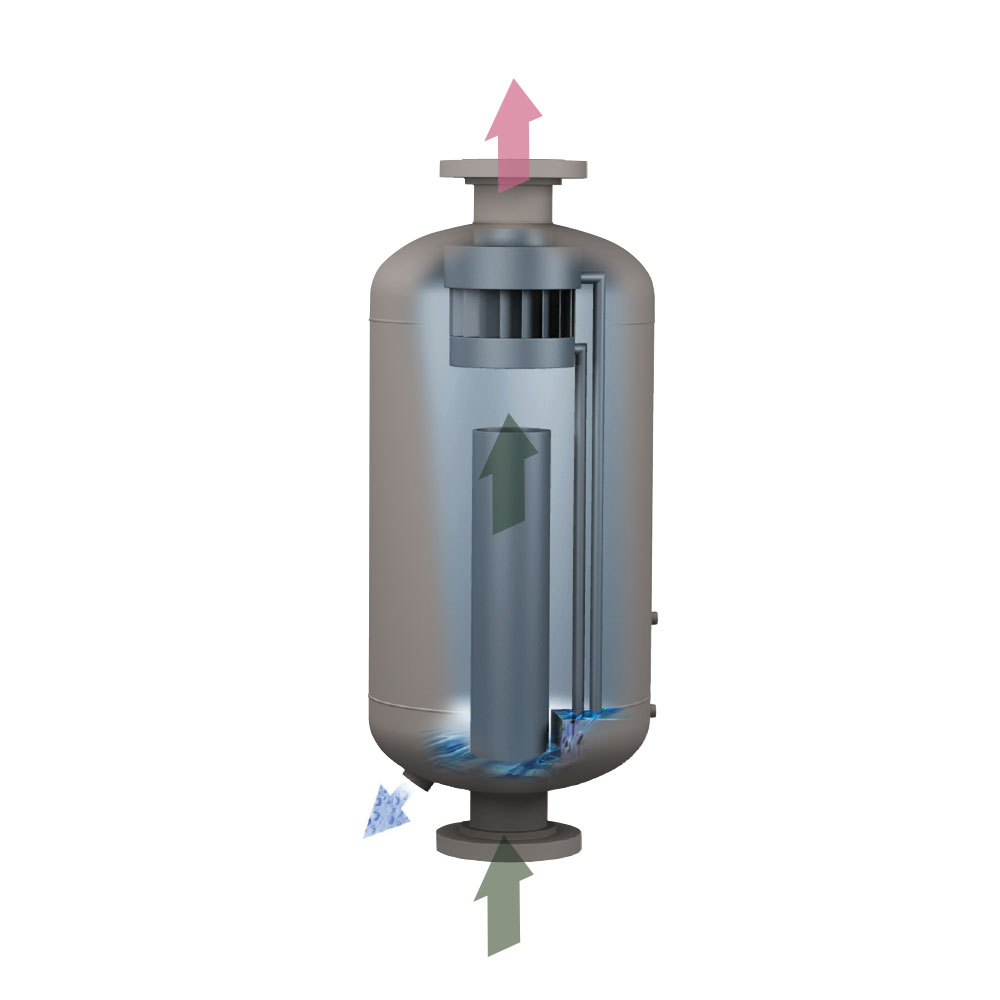

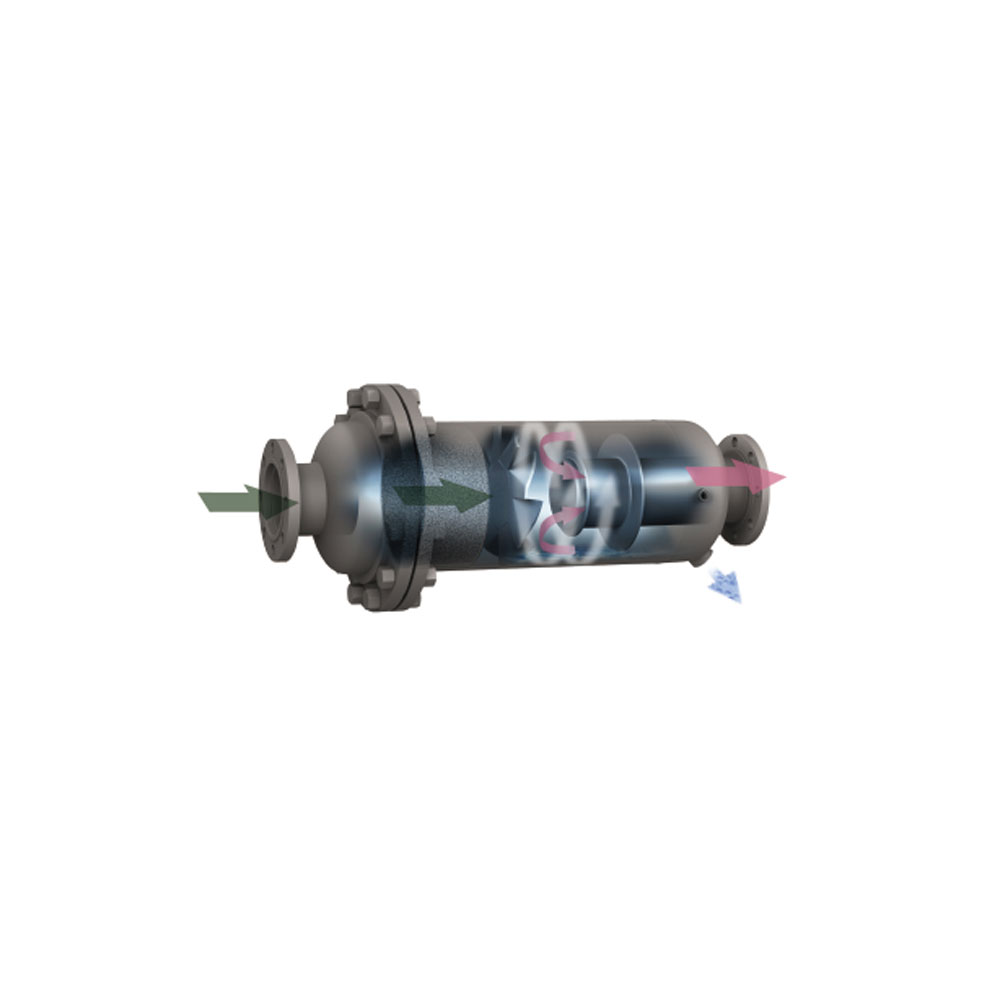

The unique two-stage design removes 99% of all liquid and solid particles larger than 4 microns in size. Standard, one-stage separators are only capable of removing particles larger than 10 microns in size. The Eaton Coalescer Separator’s efficiency far exceeds that of any other type of centrifugal, cyclone, turbine, or vane type separator.

Features & Benefits:

- Compact Design

- Easy Maintenance

- Three Flow Configurations

- Removes 99% of Liquid and Solid Entrainment

- Particles Larger Than 4 Microns

- For Gas, Steam, or Air Applications

- High Efficiency Over Wide Flow Range