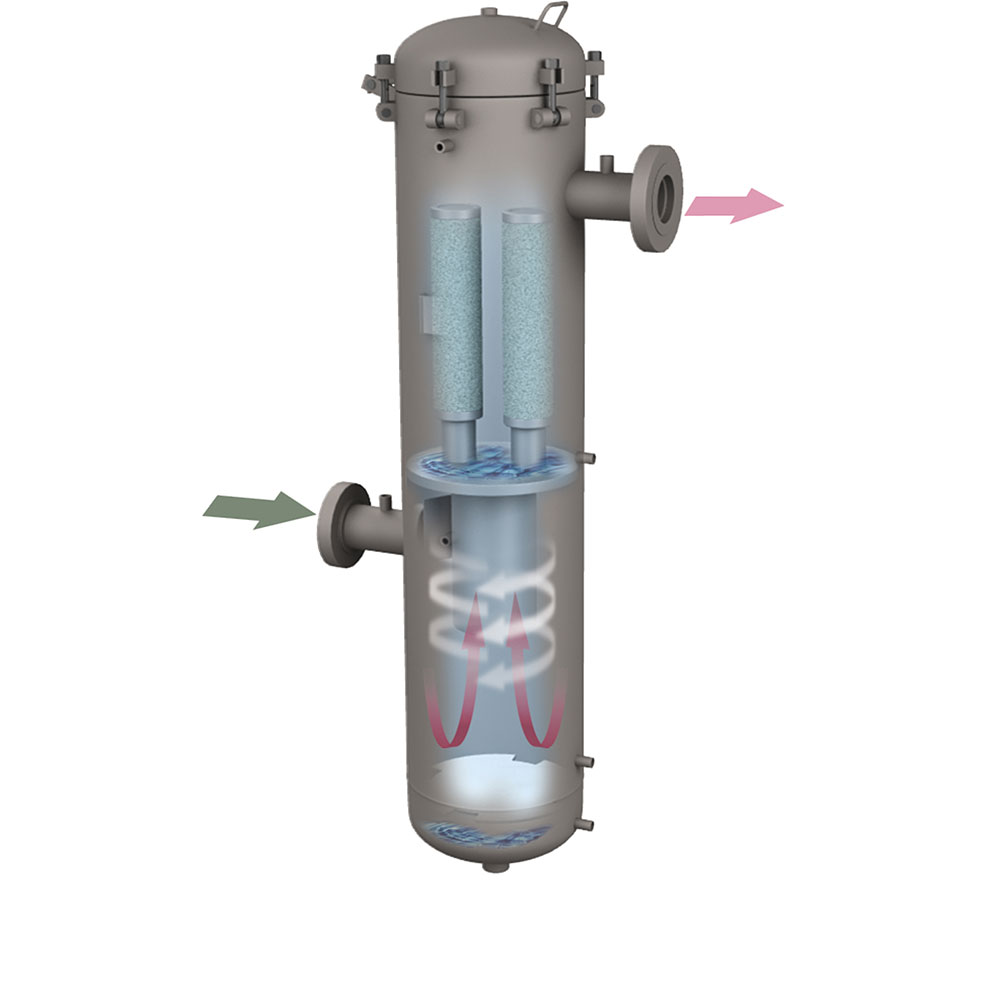

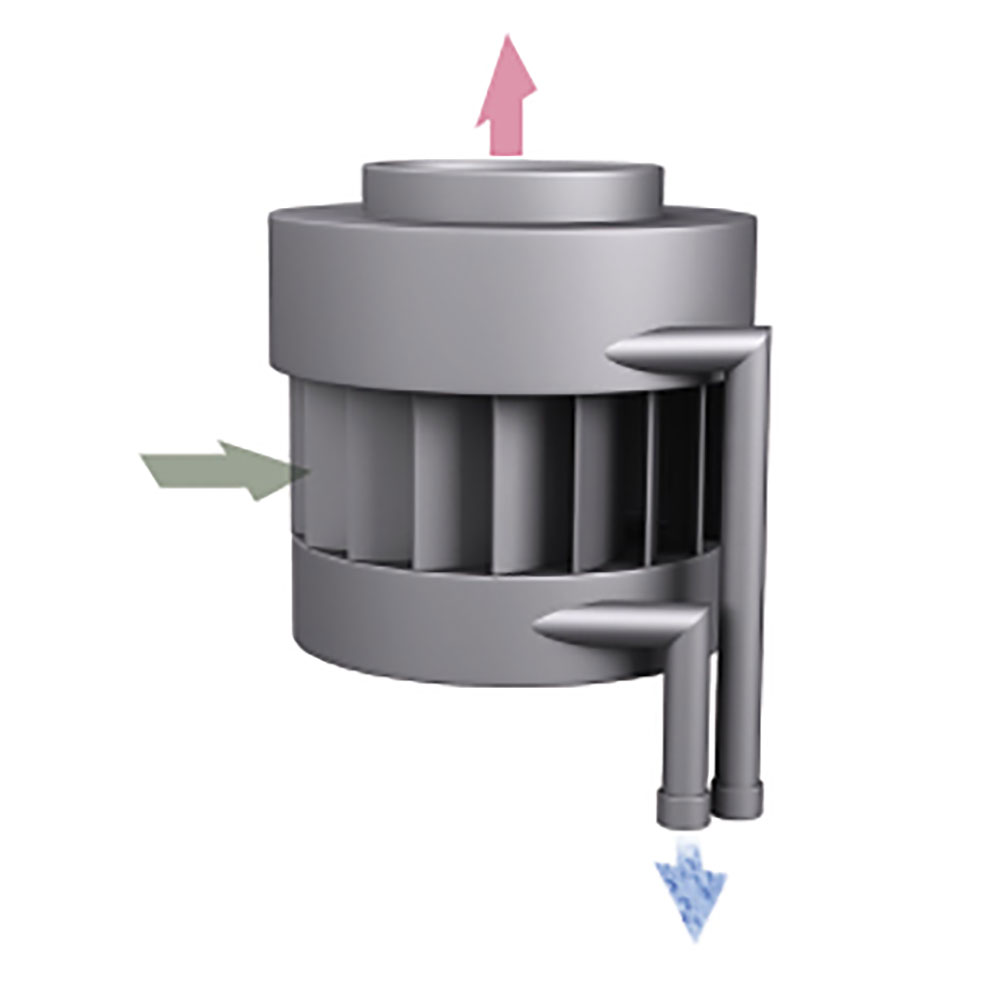

Separator Drain Traps

Separator Drain Traps

Eaton Float Drain Traps are available in a variety of models and materials of construction, featuring the Model 90-AC, Model 95-AC, Model 230-AC and Model 350-AC.

Features & Benefits:

- No Priming Required

- Stainless Steel Internal Parts

- Internal Parts Removed with Cover

- No Loss of Line Pressure

- Choice of Inlet/Outlet Configurations