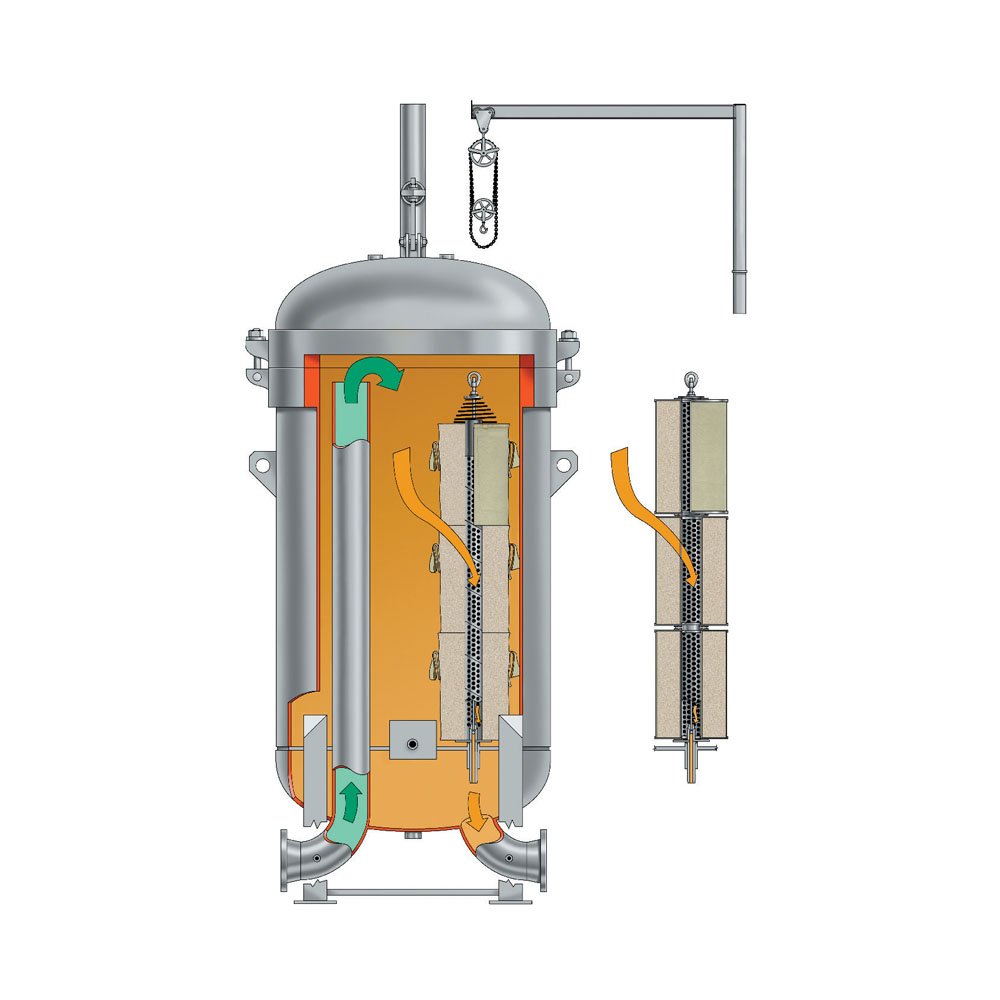

Clay Treater Housing – Model F

Clay Treater Housing - Model F

Clay treaters are usually placed upstream of a

coalescer separator system to remove surface

active agents (surfactants), color and additives from jet fuel. These unwanted contaminants may be present in fuel at the processing and refining levels or picked up from various transportation methods such as trucks, ships and pipelines that carry several types of petroleum products in addition to jet fuel.

The contaminant compounds will accumulate

and disarm the coalescer cartridge and reduce

the water coalescing efficiency of the coalescer separator. Clay treatment removes the surfactant compounds, color and additives by adsorption and delivers treated fuel to the coalescer separator while prolonging the life of the coalescer cartridges.

Features & Benefits:

- Removes surface active agents (surfactants), color and additives from jet fuel

- No internal moving parts

Removable cartridge mounting post - Designed for 150 psi (10.5 kg/cm²) @ 250ºF (121ºC)

- EI 1596 Design & Construction

- Built to ASME Code, Section VIII, stamped and certified or “CE” marked