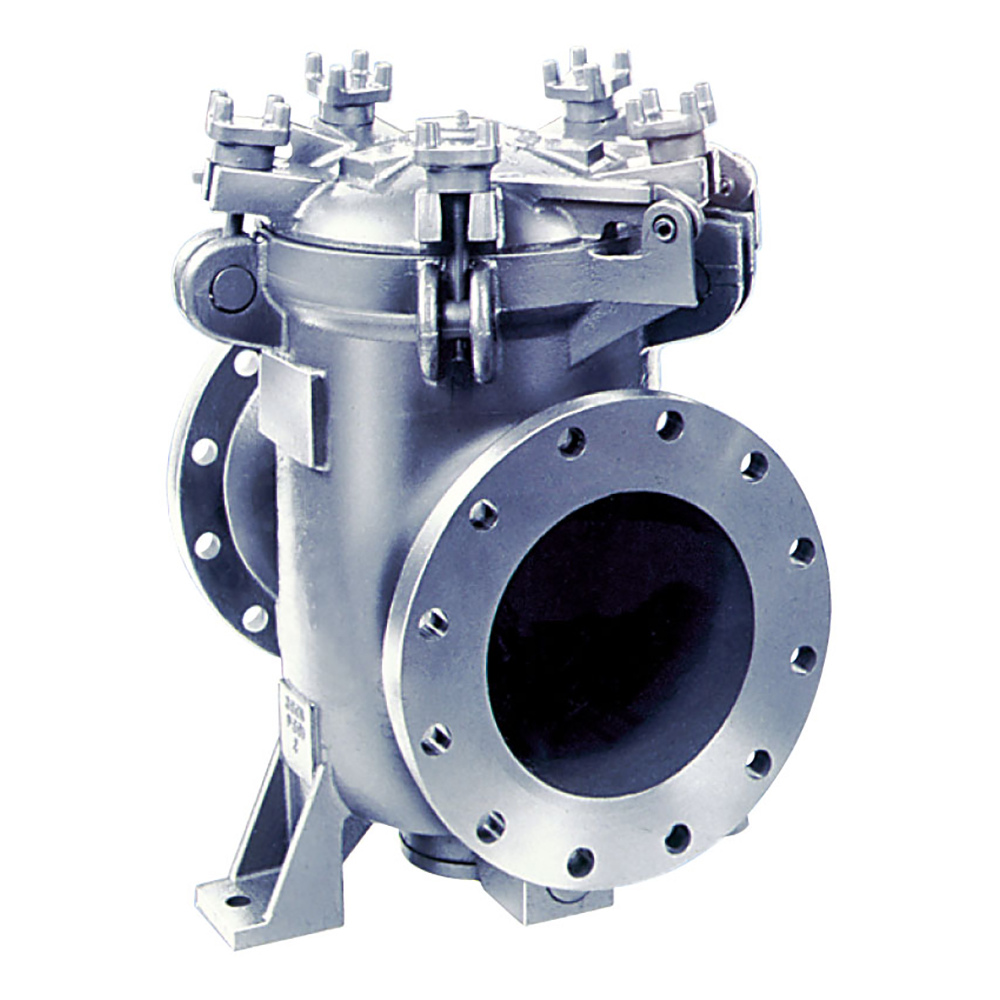

Model 510 Multi-Basket

Model 510 Multi-Basket

The Model 510 simplex strainer is unlike other large size simplex strainers because of its multi-basket design. Four strainer baskets strain the process media and give the strainer an extremely high dirt removal capability. The strainer protects system components such as flow meters, pumps, and spray nozzles.

Features & Benefits:

- Four baskets per strainer

- Bolted cover

- Straight-through flow design

- Compact

- Threaded drain

- Perforated or mesh stainless baskets standard